The background for initiating new development of international standards was the foreseeable impact of global and national regulations on HFC’s currently used in refrigeration equipment equipment. HFC’s are listed in the Kigali Amendment to the Montreal Protocol from 2016 and a phase down plan have been issued. The Paris Agreement is now the universal climate accord expected to push the governments of both developed and developing nations to commit to a low carbon future.

There are two main organizations which both have issued an standard, but be careful because they have different legal impact all depending of which marked your product are intended for.

ISO-5149:2014( The International Organization of Standardization) issued the first version of ISO 5149 in year 1993. The purpose of this standard is to promote safe design, installation, service and disposal of refrigerant equipment.

EN-378:2016(CEN - European Committee for Standards) and CEN countries are bound to comply with this---- regulation. It also specify that EN-378 standards shall be given the status as national standard, and any conflicting national standards shall be withdrawn no later than may 2017. The first version of EN-378 was released in year 2000.

As mentioned ISO has the purpose to promote safe design, and is used by some as design guidelines. Following ISO standards are well known within reefer cooling industry:

ISO 5149 is intended to minimize possible hazards to persons, property and environment from refrigerating systems. These hazards are essentially related to the physical and chemical characteristic of refrigerants as well as the temperatures and pressure in a refrigeration cycle.

ISO 20854 that allows flammable refrigerants to be used in reefer containers. This standard is published October 2019. The standard is risk based and dedicated solely to refrigerated containers and draws on established safety standards such as ISO 5149

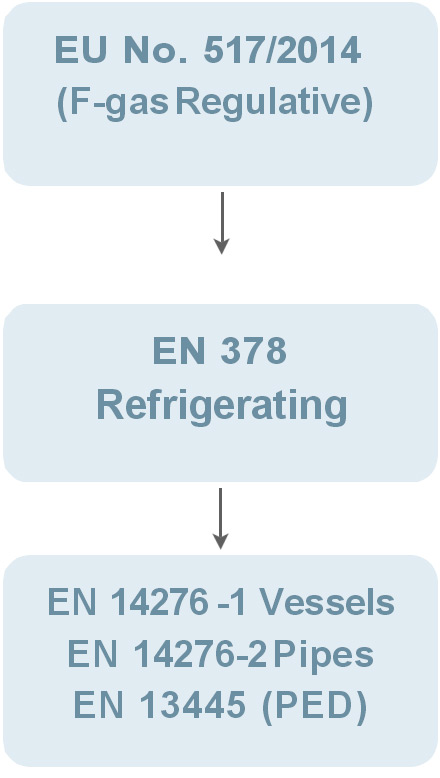

There are many similarities in the content of ISO and EN standards, but if there is an requirement to add the CE mark on the equipment we follow the EN standard system. Most people have heard the F-gas regulative(EN517/2014) mentioned several times, but are we aware what it really means for the final product?

The F-gas regulative has the main scope to phase-down use of HFC. New refrigerant with much lower Global warming potential(GWP) is replacing the previous used ones, as regulation baseline period(2009-2014) was around 2000. By 2030 users will need to be using new fluid with an average below 400.

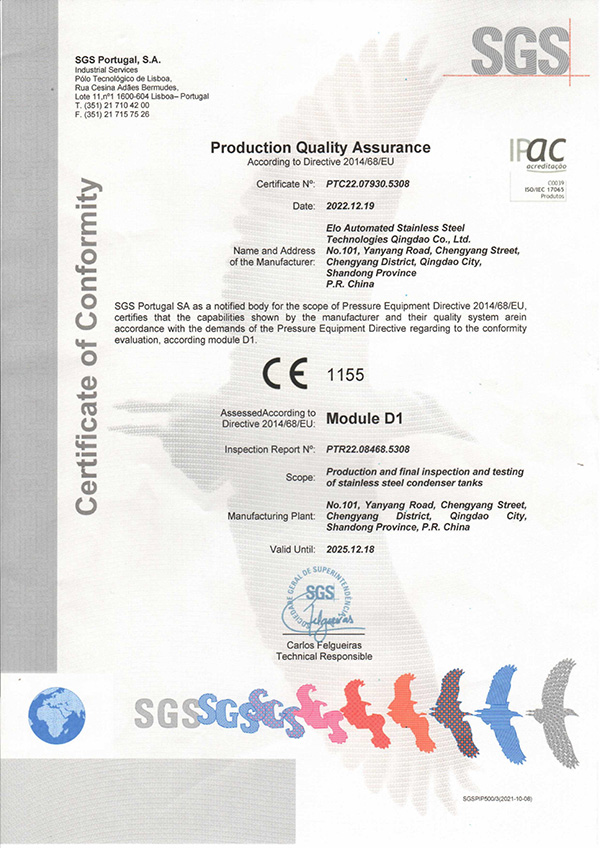

EloAutomated have designed their equipment to follow this requirement where we today have approved our component for R134A, R513A and the latest R1234yf(GWP 4). New low GWP refrigerants have different properties. Some are flammable other demand high pressure and for that reason we have updated our Quality system with new PED approval to full-fill the new requirement for new refrigerants.

Elo Stainless Steel Technologies (Qingdao) Co., Ltd successfully obtained the module D1 manufacturing system assurance certificate issued by SGS Portugal notified body No. 1155 in December 2019.

It is an important step to add PED Module D1 to our ISO 9001 and hereby secure the continuous development of our Quality system.

Incorporating and fullfilling all related standards is an substantial workload for the R&D, Production and Quality department. The collection of written documentation in the related EN standards are several thousands pages and covers a lot of details in all phases of the product from

• Calculations

• Prototype testing

• Materials with certificates

• Welding and brazing qualification,

• Tolerances and final Quality testing and inspection.

Our company has established and implemented module D1 manufacturing assurance system in accordance with PED 2014 / 68 / EU requirements, and relevant procedure documents have been confirmed by Notified Body SGS.

The welding process of pressure vessel production line and the welders are following the PQR(Procedure Qualification record), all the PQRs, WPQs(Welding Procedure Records and WOPQs(Welding Operator Performance Qualifications) have been approved by NoBo and obtained the qualification certificate.

The permanent fusion point of our product welding is qualified through SGS laboratory NDT testing, and the NDT testing experiment of welding is carried out continuously during mass production.

Copyright © Elo Automated Stainless Steel Technologies (Qingdao) Co., Ltd